Scientists at the Lawrence Berkeley National Laboratory have discovered an ingenious new way to recycle Lithium Ion batteries, and it’s so simple that even your mum could do it. Maybe.

The problem with battery recycling has always been that it’s rather cumbersome. Traditional methods involve breaking down batteries into their constituent parts, then extracting the valuable materials such as lithium, cobalt, and nickel. The process works, but it’s not exactly what you’d call efficient, and it can be quite costly. The process can also be pretty toxic, what with all the associated chemicals and gases.

Enter the boffins at the Lawrence Berkeley National Laboratory, who, after a lot of research and experimentation, have developed a new way of making batteries which makes them super simple to recycle.

The new technique uses an ingredient which they call Quick-Release Binder. Typical batteries are composed of a number of elements, including electrodes and conductive material to generate the power we need. They also contain a glue like substance called a binder, which holds the whole thing together. The problem is, it’s difficult to break down the binder when it comes time to recycle the battery.

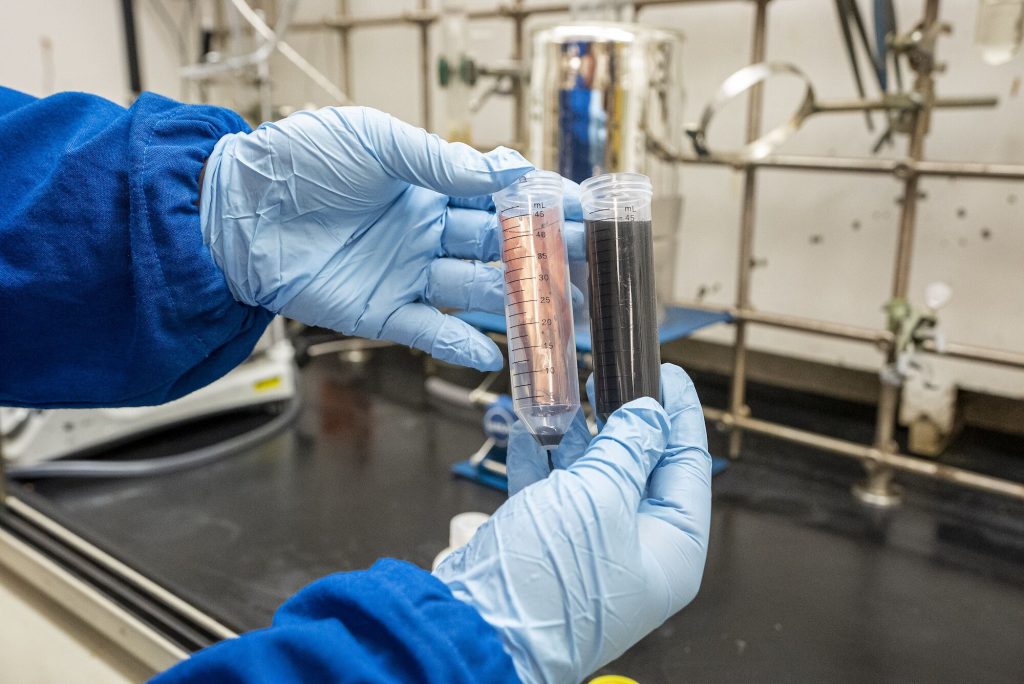

The new binder solves the problem. Instead of using harsh chemicals, the new Quick-Release Binder can be dissolved using water-based solvents. Once the binder is dissolved, the valuable metals can easily be separated and collected, ready to be reused in the production of new batteries. The new technique is specifically designed to be non-toxic, so avoiding any pollutant run off which could destroy the local biome.

The benefits of this new method are numerous. For starters, it’s a much more efficient process, meaning that it costs around a tenth of current methods. This in turn reduces the need for mining new materials. The process is also far less energy-intensive than current methods, which significantly reduces the carbon footprint.

So, what does all this mean for the future of battery recycling? It’s still early days, but things look positive. The researchers are confident that the new process can be scaled up and integrated into existing battery recycling facilities relatively quickly. And with demand for batteries increasing exponentially as we march towards a greener future, this new method could be just what we need to ensure that supply keeps up with demand.

The team has recently started talks with OnTo Technologies to commercialise the tech, and they are currently looking for licensees from around the battery industry.

They’re very bullish about the prospects for success. “The binder has a great feature that it can be ‘un-zipped’ with low-cost, environmentally benign processing, which benefits us all by improving the economic and environmental sustainability of advanced battery systems.”

It all sounds very promising indeed. Now it’s just a matter of seeing if the tech can safely leave the laboratory and provide a commercially viable option. We’re not going to hold our breath just yet. These things have a habit of taking decades to mature. But good luck to them.