The Institute of Making had its grand opening last week in central London, and we went along to get an idea of what this new venture could signal. The ‘maker movement’, as it’s called, offers a glimpse of a potential future where we don’t just passively buy and consume products, but in fact contribute in different ways to the whole product process…either by local production or hacking, repairing and recycling existing products to improve them.

The new Institute of Making in central London is just another example of how the concept is taking root in education and elsewhere as the idea becomes more mainstream. For a few generations now, we in the West have taken mass production for granted, and made full use of cheap oil to live in a throwaway society.

Suddenly things are changing as more people start re-using and recycling, and this trend is destined to grow even more as technologies such as 3D printing come online in easy to use packages. The real surprise is just how quickly the idea seems to be moving, and nowhere was this more in evidence than in the mix of people crowded into the Institute’s makerspace at last week’s public launch opening.

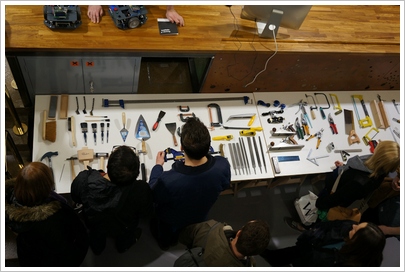

A broad mix of young and old were crammed into the small premises, sampling the tools and materials on offer, all eager to experience the pleasure of ‘making’ something. It was hard not to feel as though artisanship is now enjoying a renaissance…are people actually getting tired of mass produced products? Of course, one venue does not a revolution make, but there are many more examples of this type of shift in ideas across the world.

The Institute, which is part of University College London’s faculty of engineering, is only available for students and staff, with monthly public open days, so in that respect it fails to deliver the truly open access that venues such as ‘hackerspaces‘ offer to anyone with a screwdriver. Hackerspaces are typically more technically oriented workshops containing materials and equipment for member use, but it’s not hard to imagine a future where the technology becomes easy enough to install and use that any local community could have their own, right on their doorstep.

Instead of popping down to the hardware store to buy something, we may be dropping in to our local Repair Center to fix or hack something new to use at home. It’s interesting to note that the London Hackspace has just tripled its floorspace in new premises due to demand, making it one of the largest in the world at 6000 sq ft. It may be considered a male geek preserve at the moment, but there’s definitely something driving the growth of making and hacking, and it shows no sign of slowing down.

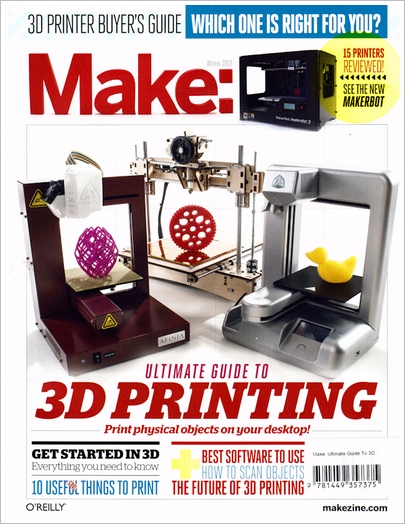

The most obvious example of this is the rise and rise of the Maker Faires and the ancillary Make: magazine franchise. Established 7 years ago in the US, the faires are part hobbycraft expos, part geek clubs, with a strong DIY ethic at the core. The shows are slowly gaining fans, as more people develop an interest in tinkering with technology and crafts, and while education is still a fundamental part of the message, the economic climate is doing its part to push the DIY ethos into more people’s attention.

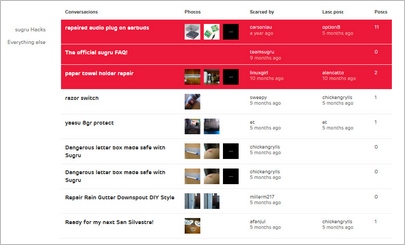

Another company which clearly shows how the concept of re-use and recycle is taking hold is Sugru, a startup which has developed a line of clever rubber putties for repairing and modifying items. With over 150,000 customers now fixing shoes, taps, pens, fencing foils, laptop chargers and in fact just about anything you can think of, this is clearly a product which has found a home in people’s hearts. A quick browse of the Sugru Gurus site, which features home grown hacks using the materials, shows just how creative people can be when given the opportunity.

And opportunity there will be in spades once 3D printers become mass market friendly in a big way. Right now there are around a dozen or more models available on the market, some in very early development, others more mature. The prices range from $500 and upwards, and there’s no getting away from the fact that you need to be a little geeky to even think of using one of these things right now. There’s the accessories to buy, design drawings to download, the materials to source and select, and a bunch of things which instantly bar the man in the street from becoming a happy user.

But already the signs are that the pendulum is moving towards more kitchen table friendly products, models like the Robo3D, which at $599 is one of the cheapest available, indicate that things are starting to change. We first talked about the potential for 3D printing back in 2009, and it looks as though we’re on the verge of seeing mass market products come to life within the next couple of years.

So, how long will it be before we’re all making our own clothes, household products and replacement parts? Well the first rule of innovation is it always takes at least 10 years to perfect, optimize for price and deliver to a mass market. So with that as a yardstick we can probably safely point to 2017 as an estimated date when the technology will be easy enough to use, materials and designs will be available everywhere and they will be fast enough to deliver what we want, when we want.

In reality we need an Apple Corp to come up with the ultimate consumer product and technology (imagine an iTunes for product designs) and we’ll be set. Don’t worry, it will happen. Somewhere, somehow.